AADIRAJA M

DEPARTMENT OF MECHANICAL ENGINEERING

VELAMMAL COLLEGE OF ENGINEERING AND TECHNOLOGY - MADURAI

3-D PRINTING TECHNOLOGY

OUTLINE

3D PRINTING

1.

Introduction

2.

Process flow

3.

Traditional vs Additive manufacturing

4.

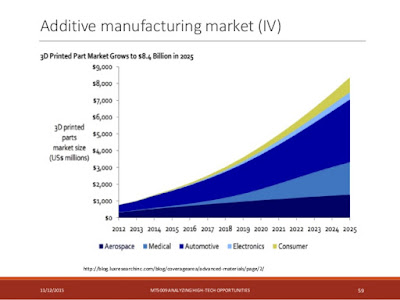

Emerging economics

5.

History

TYPES

1. Stereolithography

2. Digital light processing

technology

3. Fused deposition modelling

(FDM) technology

4. Selective laser sintering

(SLS) technology

5. Selective laser melting (SLM)

technology

6. Electron beam melting (EBM)

technology

7. Laminated object

manufacturing (LOM) technology

8. Binder jet (BJ) technology

9. Material jet or Polyjet

technology

WORKING PRINCIPLE

APPLICATION AND PRODUCTS

1.

Aerospace

industry

2.

Space station

3.

Automotive industry

4.

Defense

5.

Medical industry

6.

Growing service

market

MATERIAL SCIENCE

FUTURE TECHNOLOGY

3-D PRINTING:

· 3-D PRINTING

is a form of additive manufacturing technology where a three dimensional object

is created by laying down successive layers of material. It is also known as rapid prototyping, is a mechanized

method whereby 3-D objects are quickly made on a reasonably sized machine

connected to a computer containing blueprints for the object.

3-D PRINTING = 3-d dimensional

object

· It

is used in a variety of industries including jewelry, footwear, industrial

design, architecture, engineering and construction, automotive, aerospace,

dental and medical industries, education and consumer products.

· 3-D printing is very efficient and makes it

possible for everyone to have their designs produced, regardless of production

numbers. This really makes production capacity first only accessible to

companies directly available to anyone on the internet.

|

The

main advantages of using 3-d printing are Rapid prototyping, Reduce cost,

Manufacturing speed, housing, Environment friendly, more jobs e.t.c,

TRADITIONAL FABRICATION

Traditional fabrication methods involve a great

deal of effort, expense, and time. Specialists often have to create

individualized molds, assemble multiple components, and construct items from

multiple pieces. The process can involve many different materials, a wide

variety of highly trained workers, and several expensive trials before the

perfect object is finally created.

3-D

PRINTING FABRICATION

FOR MORE DETAILS:

HISTORY

Although 3D printing

is on the cutting edge of today’s technology, it really goes back to 1983, when

Charles Hull invented the stereo lithography (SLA) machine. Hull went on to

found 3D systems and launched a whole new industry. SLA machines were later

called 3D printers. During the last decade, this technology has rapidly

advanced, bringing about many practical applications. He

named the technique as Stereo lithography and obtained a patent for the

technique in 1986. While Stereo

lithography systems had become popular by the end of 1980s, other similar

technologies such as Fused Deposition Modeling (FDM) and Selective Laser

Sintering (SLS) were introduced. In 1993, Massachusetts Institute of Technology

(MIT) patented another technology, named "3 Dimensional Printing

techniques", which is similar to the inkjet technology used in 2D

Printers. In 1996, three major products, "Genisys" from Stratasys,

"Actua 2100" from 3D Systems and "Z402" from Z Corporation,

were introduced. In 2005, Z Corp. launched a breakthrough product, named

Spectrum Z510, which was the first high definition color 3D Printer in the

market.

FOR MORE DETAILS:

3-D PRINTING TECHNOLOGY TYPES

SLA is a fast prototyping process. Those who use this technology are serious about accuracy and precision. It can produce objects from 3-D CAD data (computer-generated) files in just a few hours. This is a 3-D printing process that’s popular for its fine details and exactness. Machines that use this technology produce unique models, patterns, prototypes, and various production parts. They do this by converting liquid photopolymers (a special type of plastic) into solid 3-D objects, one layer at a time.

The plastic

is first heated to turn it into a semi-liquid form, and then it hardens on

contact. The printer constructs each of these layers using an ultra violet

laser, directed by X and Y scanning mirrors. Just before each print cycle, a

recoater blade moves across the surface to ensure each thin layer of resin

spreads evenly across the object. The print cycle continues in this way,

building 3-D objects from the bottom up.

Once

completed, someone takes the 3-D object from the printer and detaches it

carefully from the platform. The 3-D part will usually have a chemical bath to

remove any excess resin. It’s also common practice to post-cure the object in

an ultra violet oven. What this does is render the finished item stronger and

more stable. Depending on the part, it may then go through a hand sanding

process and have some professional painting done. SLA printing has become a

favored economical choice for a wide variety of industries. Some of these

include automotive, medical, aerospace, entertainment, and also to create

various consumer products.

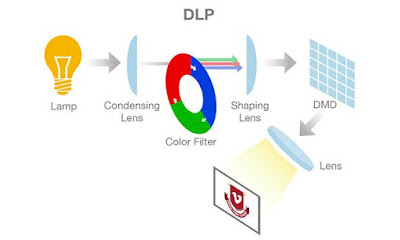

FOR MORE DETAILS: DLP is the oldest of the 3D printing technologies, created by a man calledLarry Hornbeck back in 1987. It’s similar to SLA (see above), given that it also works with photopolymers. The liquid plastic resin used by the printer goes into a translucent resin container. There is, however, one major difference between the two, which is the source of light. While SLA uses ultra violet light, DLP uses a more traditional light source, usually arc lamps.

This process results

in pretty impressive printing speeds. When there’s plenty of light, the resin

is quick to harden (we’re talking seconds). Compared to SLA 3-D printing, DLP

achieves quicker print times for most parts. The reason it’s faster is because

it exposes entire layers at once. With SLA printing, a laser has to draw out

each of these layers, and this takes time.

Another plus point for DLP printing technology is that it is

robust and produces high resolution models every time. It’s also economical

with the ability to use cheaper materials for even complex and detailed

objects. This is something that not only reduces waste, but also keeps printing

costs low.

FOR MORE DETAILS:

https://www.youtube.com/watch?v=1oRsxdpVhkA

3. SELECTIVE LASER SINTERING (SLS) TECHNOLOGY: An American businessman, inventor, and teacher named Dr.Carl Deckard developed and patented SLS technology in the mid-1980s. It’s a 3D printing technique that uses high power CO2 lasers to fuse particles together. The laser sinters powdered metal materials (though it can utilize other materials too, like white nylon powder, ceramics and even glass). Here’s how it works:

The

build platform, or bed, lowers incrementally with each successive laser scan.

It’s a process that repeats one layer at a time until it reaches the object’s

height. There is un-sintered support from other powders during the build

process that surround and protect the model. This means the 3D objects don’t

need other support structures during the build. Someone will remove the

un-sintered powders manually after printing. SLS produces durable, high

precision parts, and it can use a wide range of materials.

It’s a

perfect technology for fully-functional, end-use parts and prototypes. SLS is

quite similar to SLA technology with regards to speed and quality. The main

difference is with the materials, as SLS uses powdered substances, whereas SLA

uses liquid resins. It’s this wide variety of available materials that makes

SLA technology so popular for printing customized objects.

FOR MORE DETAILS:

SLM

made its debut appearance back in 1995. It was part of a German research

project at the Fraunhofer Institute ILT, located in the country’s most western city of Aachen.

Like SLA (see above), SLM also uses a high-powered laser beam to form 3D parts.

During the printing process, the laser beam melts and fuses various metallic

powders together. The simple way to look at this is to break down the basic

process like thus

Powdered material + heat + precision + layered

structure = a perfect 3D object.

As the

laser beam hits a thin layer of the material, it selectively joins or welds the

particles together. After one complete print cycle, the printer adds a new

layer of powered material to the previous one. The object then lowers by the

precise amount of the thickness of a single layer. When the print process is

complete, someone will manually remove the unused powder from the object. The

main difference between SLM and SLS is that SLM completely melts the powder,

whereas SLS only partly melts it (sinters). In general, SLM end products tend

to be stronger as they have fewer or no voids.

FOR MORE DETAILS: A Swedish company called Arcam AB founded EBM in 1997. This is a 3D printing technology similar to SLM (see above), in that it uses a powder bed fusion technique. The difference between the two is the power source. The SLM approach above uses high-powered laser in a chamber of noble, or inert gas. EBM, on the other hand, uses a powerful electron beam in a vacuum. Aside from the power source, the remaining processes between the two are quite similar. EBM’s main use is to 3D print metal parts. Its main characteristics are its ability to achieve complex geometries with freedom of design. EBM also produces parts that are incredibly strong and dense in their makeup. Doesn’t need extra auxiliary equipment for the 3D printing process.

FEATURES OF EBM

Has

increased efficiency using raw materials.

Lessens

lead times resulting in parts getting to market faster.

Can

create fully functional, durable parts on demand for wide-ranging industries.

FOR MORE DETAILS:

7. LAMINATED OBJECT MANUFACTURING (LOM) TECHNOLOGY:

A

Californian company called Helisys Inc. (now Cubic Technologies), first

developed LOM as an effective and affordable method of 3D printing. A US design

engineer called Michael

Feygin, a pioneer in

3D printed technologies—originally patented LOM.

LOM is

a rapid prototyping system that works by fusing or laminating layers of plastic

or paper using both heat and pressure. A computer-controlled blade or laser

cuts the object to the desired shape. Once each printed layer is complete, the

platform moves down by about 1/16th of an inch, ready for the next layer. The

printer then pulls a new sheet of material across the substrate where it’s

adhered by a heated roller. This basic process continues over and over until

the 3D part is complete.

WORKING PROCESS

Sheet

is adhered to a substrate with a heated roller.

Laser

traces desired dimensions of prototype.

Laser

cross hatches non-part area to facilitate waste removal.

Platform

with completed layer moves down out of the way.

Fresh

sheet of material is rolled into position.

Platform

downs into new position to receive next layer.

The process is repeated.

BJ is a 3D printing process that uses two types of materials to build objects powder-based material (usually gypsum) and a bonding agent. As the name suggests, the “bonding” agent acts as a strong adhesive to attach (bond) the powder layers together. The printer nozzles extrude the binder in liquid form similar to a regular 2D inkjet printer. After completing each layer, the build plate lowers slightly to allow for the next one. This process repeats until the object reaches its required height.

The Massachusetts Institute of Technology

(MIT) first invented BJ 3D printing.

It’s not possible to get super high-resolution or overly

rugged 3D objects with BJ printing, but there are other advantages. For

example, these printers allow you to print parts in full color. To do this, you

simply add color pigments to the binder, which typically include black, white,

cyan, yellow, and magenta. This technology is still advancing, so expect more

great things to come in the future. At the time of writing, some applications

of BJ 3D printing include rapid prototyping, and various uses in the aerospace,

automotive, and medical industries.

FOR MORE DETAILS:

9. POLY JET TECHNOLOGY:There are also Polyjet MJ 3D printers, which use photopolymer-resins rather than synthetic waxes. Polyjet technology also offers very good resolution. Unlike digital wax printers, people use Polyjet devices to create parts for a wide range of industries. Wax casting has been a traditional process where the user produces high-quality, customizable jewelry. The reason it gets a mention here is because of the introduction of 3D printing. Thanks to the arrival of this technology, wax casting is now an automated process. Today, MJ 3D printers produce high-resolution parts, mainly for the dental and Jewelry industries,

For

jewelers who want to experiment with various casts—as most jewelers do—MJ is

now their leading 3D technology. At the time of writing, there are a few

high-quality professional wax 3D printers on the market. Here’s how they work:

Once

the 3D model (CAD file) is uploaded to the printer, it’s all systems go. The

printer adds molten (heated) wax to the aluminum build platform in controlled

layers. It achieves this using nozzles that sweep evenly across the build area.

As soon as the heated material lands on the build plate it begins to cool down

and solidify (UV light helps to cure the layers). As the 3D part builds up, a

gel-like material helps to support the printing process of more complex

geometries. Like all support materials in 3D printing, it’s easy to remove it

afterward, either by hand or by using powerful water jets. Once the part is

complete you can use it right away, no further post-curing necessary.

FOR MORE DETAILS:

WORKING PRINCIPLE OF

3-D PRINTING:

The basic concept behind all 3-D printers is the same.

3-dimensional CAD drawings are sliced into layers ranging from approximately

0.09 to 0.25 millimeters thick depending on the machine being used. Each slice

represents a single layer of the constructed object. Different printers use

different materials and different binding processes, but generally a powder of

ceramic, nylon, or even metal is used as the base material and fused together

into the pattern for the layer currently being created. After the completion of

a layer, the machine moves on to the next layer until it is completed.

FOR MORE DETAILS:

APPLICATIONS AND PRODUCTS IN 3-D PRINTING:

1. AEROSPACE: Like many industries, aerospace is leveraging 3-D printing to improve the performance of assets, reducing maintenance requirements, consolidating components and saving fuel costs with lighter parts.

Boeing, a pioneer in 3D

printing, has printed 22,000 components that are used in a variety of

aircraft.30 For example, Boeing has used 3D printing to produce environmental

control ducting (ECD) for its new 787 aircraft. With traditional techniques,

the ECD is created from up to 20 parts due to its complex internal structure.

2. SPACE STATION:Looking ahead, NASA is exploring 3D printing as a service (3DPaaS) for rapid pre-prototype work. “We are bullish on 3D printing,” says Tom Soderstrom, IT chief technology officer at NASA Jet Propulsion Laboratory. “3D printing makes it easier to capture the imagination of the mission concepts. We can see what others are imagining.” Engineers could use 3DPaaS to rapidly obtain peer reviews, additional design concepts and approval to prototype. Initial prototyping and iterations would be done using low-cost, fast-turnaround open source CAD tools and 3D printers. “We like the open source, open design approach. It would allow us to get outside ideas about the designs more easily and to get started much sooner,” Soderstrom adds.

Both organizations are

developing tools, processes and systems for directly manufacturing in space,

avoiding the costly and decade-long planning cycles required to send a rocket

into space with the necessary replacement parts and tools. Made in Space has a

contract with NASA and is currently conducting zero gravity tests, with plans

to trial 3D printing on the International Space Station.

FOR MORE DETAILS:

3. AUTOMOTIVE:

WORLD FIRST 3-D PRINTED CAR

For years, major

automotive manufacturers have been using 3D printing for prototyping. However,

the automotive industry is poised to begin applying the process to more than

just prototypes of small custom parts.

Take, for example, the Urbee, billed as the world’s first printed car. The two passenger Urbee, created by KOR EcoLogic, dismisses preconceptions about limits to 3D printing sizes. To be clear, not all parts are 3D–printed — just the shell of this hybrid prototype car — though interior components are planned to be 3D printed.38 (See Figure 11.) The Urbee, which could be in low-volume production by 2014,39 has planted the seed for mass customization of large-scale car components. Watch for unique car styles, designs and shapes to appear in the near future. FOR MORE DETAILS: 4. DEFENSE:In the future, it may be possible for the military to print replacement parts on the battlefield instead of relying on limited spares or the supply chain. While this is still some time away, there are developments that suggest movement in the right direction. For example, the Trainer Development Flight (TDF) facility at Sheppard Air Force Base in Texas is using 3D printing to develop training aids for the Air Force and other U.S. Department of Defense branches. Given the highly specialized nature of the equipment, such as unmanned aerial vehicles (UAVs), and the low volumes required, using original parts or even manufacturing replicas is a lengthy and expensive exercise. However, using 3D printing in combination with traditional manufacturing technique.

The most inspiring use

of 3D printing is in the healthcare industry, where 3D printing has the potential to save lives or dramatically improve them. 3D printing in healthcare

still has some years to go before mass adoption, but early developments to

create tissue, organs, bones and prosthetic devices provide a glimpse of how

lives may be improved.

The basic idea is to

print living cells — and the biomaterials that hold cells together — into a 3D

shape. This organ or tissue structure would then be implanted into the body,

where it would continue to develop. The kidney project is based on earlier work

that used cells and biomaterials to engineer a “miniature” kidney that was able

to produce a urine-like substance when implanted in a steer.

In addition, there are a growing number of applications for 3D printing in surgery. For example, the Walter Reed Army Medical Center has created and successfully implanted.

FOR MORE DETAILS:

6. GROWING SERVICE MARKET:

3D printers make it economical to create highly unique products that quench the rising thirst for personalization. Whether it is a smartphone case personalized with your name, an avatar from World of Warcraft or a self-designed robot toy, there are a range of services like Fresh fiber, Figure Prints, My Robot Nation and Sculpteo at one’s disposal. The consumer market is buzzing with affordable custom products, all available through the Internet using “as a service” techniques. Expect to see 3D printing stores in a shopping mall near you soon!

FOR MORE DETAILS:

MATERIAL

SCIENCE OF 3-D PRINTING TECHNOLOGY

1. POLYLACTIC

ACID (PLA):

In fact, Polyactic Acid (PLA) is biodegradable. It is often used in food handling and medical implants that biodegrade within the body over time. Like most plastics, it has the potential to be toxic if inhaled and/or absorbed into the skin or eyes as a vapor or liquid (i.e. during manufacturing processes).

Poly(lactic acid) or Polyactic acid or polylactide (PLA) is a biodegradable and bioactive thermoplastic aliphatic polyester

derived from renewable resources, such as corn starch (in the United States and

Canada), cassava roots, chips or starch (mostly in Asia), or sugarcane (in the

rest of the world).

PLA Volume: 0.80 cm^3/g or 800 cm^3/kg. 1.75 mm filament length for 1 kg spool: ~ 330 meters / ~ 1080

feet. 3.00 mm filament length

for 1 kg spool: ~ 110

meters / ~ 360 feet.

FOR MORE DETAILS:

2. ACRYLONITRILE BUTADIENE STYRENE (ABS):

ABS

plastic (acrylonitrile butadiene styrene) is

part of the thermoplastic polymers family.

It is a material commonly used in personal or household 3D printing, which is

done using primarily FDM or FFF 3D Printing. It is popular in large part

because it is lightweight, has good impact strength, and is affordable.

The melting temperature of

ABS plastic is 200°C (392°F), making it ideal for use in relatively safe

machines that are easy to operate (the safety of household machines is

important).

ABS plastic is used by 3D FDM or FFF printers and comes in the

form of a long filament wound around a spool. Operating the 3D printer is

fairly simple: the ABS strand is guided into an extrusion head or extruder

(also called a 3D printing nozzle) that heats the ABS to its melting point in

order to liquefy it. Once liquefied, the material is deposited layer by layer

on a 3D printing platform (which may or may not be heated. the main

benefits of 3D printing with a good quality ABS filament include

·

Heat resistant

·

Finished part is easy to sand and

glue

·

Easily soluble in acetone

·

Great plastic properties

·

Nice smooth finish

·

Solidifies quickly

FOR MORE DETAILS:

3. POLYVINYL ALCOHOL (PVA):

Poly (vinyl alcohol) (PVOH, PVA, or PVAL) is a water-soluble

synthetic Polymer.

It has the idealized formula [CH2CH (OH)] n.

It is used in papermaking, textiles, and a variety of coatings. It is white

(colorless) and odorless. It is sometimes supplied as beads or as solutions in

water.

FOR MORE DETAILS:

4. Nylon:

Nylon filament is an incredibly strong, durable, and versatile 3D

printing material. Flexible when thin, but with very high inter-layer

adhesion, nylon lends itself well to things like living hinges

and other functional parts.

Nylon 11 or

Polyamide 11 (PA 11) is a polyamide and bio plastic, a

member of the nylon family

of polymers. It is produced from castor beans by Arkema under the trade name

Rilsan. It is produced by polymerization of 11-aminoundecanoic acid. Nylon-12 is

primarily used as a

bulking agent, and opacifying agent, according to CosmeticsInfo.org.

Functions: Nylon-12 is a polymer made of repeating

units linked by amide bonds and is used because

of its unique properties as a flexible solid.

FOR MORE DETAILS:

FUTURE

OF 3D PRINTING TECHNOLOGY:

3-D printing is moving in several directions at this time and all indications are that it will continue to expand in many areas in the future. Scientists and engineers use 3D printing technology to replace lost limbs and businesses use it to prototype new products. Artists use 3D printers to build wax sculptures that are then cast in to metal statues. In the future, 3D printing could change the way we interact with isolated places. This technology shows enormous potential for tech-savvy developers that work in developing countries. It could even help with disaster relief, considering the difficulty of finding small, specialized parts in many areas of the world. With a single 3D printer, crucial mechanical components can be printed on-site without having to wait for shipping.

The same concept applies to space

travel. Astronauts could use 3D

printing technology for emergency repairs, potentially allowing for even

greater distances of space exploration. As this technology progresses, these

machines revolutionize the way we produce and store materials. Unused filament

can be crushed and reused. Recycling plants may eventually start turning

discarded materials into usable 3D printing filament. The growth of the

industry moved this technology from the industrial space onto the consumer

desktop. With time, 3D printing technology could become a household resource.

FOR MORE DETAILS:

|

thanks for sharing!

ReplyDeletehttps://cgifurniture.com/